Six wide-ranging business fields

KOA Textile Industry is currently expanding its business fields centering around its six business fields;

the “Tire Cord Department”, “Filament Twisted Yarn Department”, “Spun and Twisted Yarn Department”, “Air Suspension Department”, “Lifestyle Products Department”, and “Health Food Ingredients Department”, and is continuing to create new value.

-

Tire Cord Department

This has been a core department since the company’s foundation. The company’s strength lies in the fact that the range of the warp’s twist is extremely wide, with custom made items able to be produced with a warp of 25,000-30,000 denier.

-

Filament Twisted Yarn Department(hose reinforcement textiles etc.)

Processes textile material that is “Low in ductility, high in strength” into twisted yarn “without any knots” up to a maximum wound quantity of 10KG.

-

Spun and Twisted Yarn Department

From single-thread twine to a maximum of 12 threads in one, the only company in the world that can produce folded yarn with no defects or knots, using optical sensors to eliminate flaws.

-

Air Suspension Department

Through the use of our own equipment, we supply almost 100% of all twisted yarn cord for use in domestic air suspension, and we have made good spooling quality and stability at high speeds a reality.

-

Lifestyle Products Department

In co-development with a manufacturer of compound materials, our twisted yarn is used in areas such as even more highly-adhesive dental floss, and bristles for the cutting-edge model “motor head brush” in cyclone vacuum cleaners.

-

Health Food Ingredients Department

We are engaged in the factory cultivation of a succulent plant known as the Ice Plant which uses biosynthesis to produce pinitol. This is said to work as an osmotic pressure adjusting substance to increase the metabolization of glucose.

List of Equipment

-

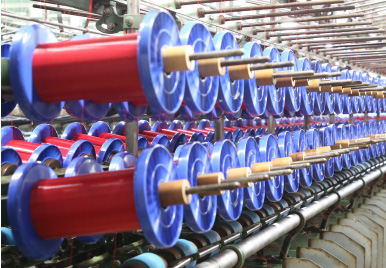

Ring twister

Total of 44 units (6198 spindles)Manufacturer Ring Diameter No. of Spindles No. of Units Normal Turnover Main Use Kioritz 10 inches 12 2 1800 Ultra-thick items Kaji Ironworks 8 1/2 inches 108 2 2850 FH/C 〃 8 1/2 inches 104 1 2850 FH/C 〃 6 1/2 136 4 5000 NT/C 〃 6 1/2 136 1 5000 ET/C 〃 6 1/2 128 1 3000 PE 〃 5 1/2 132 1 4000 VT/C 〃 5 1/2 132 6 5000 NT/C 〃 5 1/2 140 2 5000 NT/C 〃 4 1/2 200 2 5200 ET/C 〃 4 1/2 168 1 5200 NT/C 〃 4 196 3 5500 NT/C Chiyoda Kikai Works 5 1/2 138 6 4500 AS 〃 4 1/2 200 2 5200 NT/C Suga Manufacturing 5 1/2 138 6 4800 NT/C Settsu Boki 5 1/2 138 3 4800 NT/C Obu Sangyo 3 1/2 216 1 6500 NT/C -

Tire cord fabric weaving looms

8 unitsManufacturer Model Nominal Width Method Normal Turnover No. of Units Tsudakoma Corp FR-001 190cm Tuck-in rapier 400 7 〃 ZAX-9200i-TC 191cm Air-jet tuck-in 900 1 -

Winder

23 units (959 spindles)Manufacturer Model No. of Units Traversing Width Normal Yarn Speed No. of Extension Spindles Kozu Seisakusho SP-8-12SE 3 8 inches 350 15 〃 〃 4 〃 350 40 〃 SP-12-12SE 1 12 inches 350 10 〃 SP-8-12 8 8~12 350 48 〃 GT-model multiple-thread loom 1 6 inches 500 20 Murata Machinery #23 Drum-model doubling 2 〃 350 114 〃 〃 1 〃 350 30 〃 #608 Cam-type doubling 2 〃 500 40 Hoki Kiryo RT 1 5 inches 500 2 -

Double twister

9 Units (2514 spindles)/Capable of 71MT of production monthlyManufacturer Model No. of Units No. of Stretching Spindles Normal Turnover Monthly Production Capacity Kaji Ironworks SLP-400S 2 120 5000 22MT Murata Machinery #363-LL 3 362 9000 22MT 〃 #363-L 3 372 9000 23MT 〃 #373 1 72 5000 4MT -

Dry-heat treatment device

Manufacturer Model Temperature Range Treatment Capacity Sawamura Co., Ltd./Other Thermocouple detector/Sirocco fan/Force-circulation convection current batch-type MAX200C 1.4tons -

Test/Inspection equipment

20C/65%RH (conforms to JIS-1017) Total air conditioning/Set up windowless test roomTest Items Device Name Model Full-scale Manufacturer Strength/Ductility test Autograph AG-I 5KN Shimadzu Corp. Higher # of times Electric twist tester SM 50cm Misuji Corp. Moisture content/Absolute drying Constant-temperature oven DN-42 200C Yamato Scientific Co., Ltd. Moisture content/Fiber drying Direct-reading balance AX-200 200g Shimadzu Corp. Cord gage Dial gage Mitsutoyo 10mm Shimadzu Corp. Rigidity High-polymer durometer TYPE-C 100C Kobunshi Kiki Co., Ltd. Yarn length Sizing reel Frame circumference 1m 1000m Shimadzu Corp. Twisted yarn tension Tensiometer AN200 200g Nakaasa sokki. Twisted yarn tension Tensiometer AN500 500g Nakaasa sokki. Turnover Stroboscope 2000B 18000RPM Mashintex. -

Plant factory

Triplex-type rebuilt container/Completely closed and maintenance-type/Solar simulator 100%/Organic cultivationCultivation tank 140 beds Illumination Triple-band wide LED triple-light/bed Nutriment circulation Watering-harvesting-filtration-reuse four-way system Nutriment control ph sensor, nutriment viscosity sensor, and automatic replenishment system CO2 CO2 sensor and replenishment system with electromagnetic bubble Air conditioning Temperature control and recorder via system-package air conditioning Dryer Food product drying device (able to process 50KG batches) Grinder Stainless steel, #400